Simo DC motors adopt advanced design concepts. Through optimizing the electromagnetic design and structural layout, their working efficiency has been greatly improved. Whether under light load or heavy load conditions, they can maintain stable operation, reducing the energy consumption costs for users. The high-efficiency design not only enhances the performance of the motor but also extends its service life, saving long-term operation costs for enterprises.

Simo DC motors are equipped with precise control systems, which can achieve high-precision speed and torque control. Whether for precision instruments or large-scale mechanical equipment, Simo DC motors can meet complex application requirements. Whether it is necessary to run at a high speed or to have a low speed with high torque, they can easily cope with it, providing users with stable and reliable performance.

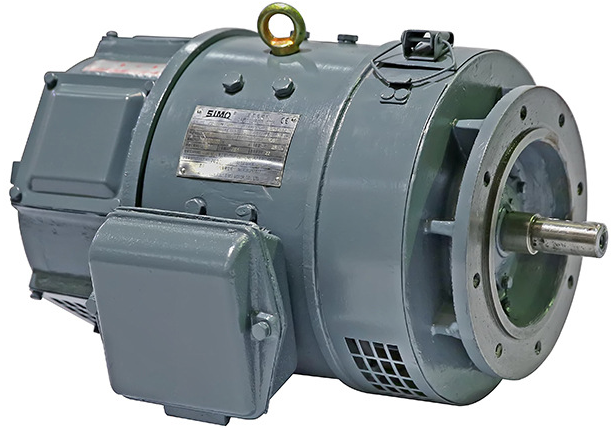

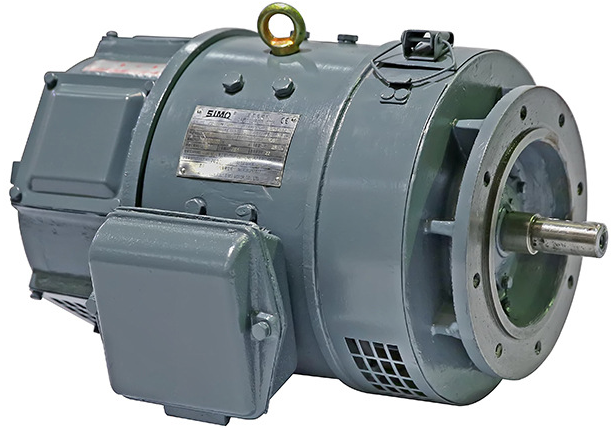

Durability is fully considered during the design of Simo DC motors. The casing is made of high-strength materials, which have the properties of dust prevention, moisture resistance, and shock resistance, and can adapt to various harsh environments. Under extreme temperature and humidity conditions, they can still operate efficiently and are widely applicable to various industrial environments. The reliability and durability of Simo motors have been recognized by many users. Many users have reported that their Simo motors still maintain good performance after running for a long time, without obvious wear or failures.

Simo DC motors focus on energy conservation and environmental protection. By optimizing the energy efficiency ratio, the energy consumption has been reduced. Under the same output power, Simo DC motors can save electricity consumption and reduce the impact on the environment, meeting the requirements of sustainable development in modern industry. At the same time, Simo motors use environmentally friendly materials to reduce the emission of harmful substances and contribute to environmental protection.

In the industrial field, Simo DC motors play a pivotal role. They are widely applied in various industrial equipment such as printing machines, steel rolling mills, extruders, and textile machines, providing stable power for industrial automation. Their high-efficiency design enables them to maintain excellent operating conditions in industrial production, whether under light or heavy loads, greatly improving production efficiency and reducing energy consumption costs. The precise control performance can meet the needs of various complex industrial equipment. Whether it is high-speed operation or low-speed with high torque, it can be easily achieved, providing a strong guarantee for the precision of industrial production. At the same time, Simo DC motors are highly durable. The casing is made of high-strength materials with dust-proof, moisture-proof, and shock-resistant properties, and they can operate stably even in harsh industrial environments, ensuring the long-term and stable production of enterprises.

Simo DC motors also have an excellent performance in the field of mining equipment. Due to the complex working environment of mining operations, the requirements for motors are extremely high. Simo DC motors can be customized according to specific needs, providing reliable power solutions for mining equipment. Their powerful power output can meet the high-load operation requirements of mining equipment such as crushers and mills. Meanwhile, the durability and stability of the motors have been fully verified in the harsh mining environment, which can effectively reduce the equipment failure rate and improve mining production efficiency.

Simo DC motors produced in Xi'an also perform outstandingly in metallurgical machinery. The metallurgical production process has very strict requirements for the performance of motors, which need to be efficient, stable, and reliable. Simo DC motors just meet these requirements. They can provide powerful power support for metallurgical machinery, improving production efficiency and product quality. Whether it is a steel rolling mill or a fan system, Simo DC motors can achieve precise speed regulation and energy-saving operation, reducing costs for metallurgical enterprises and enhancing their competitiveness.

For precision machining equipment, the high-precision requirement of power is of vital importance. Simo DC motors meet the high-precision power requirements of precision machining equipment with their precise control performance. In fields such as precision instrument machining, Simo DC motors can provide stable and reliable power output, ensuring the machining precision and quality. Their high-efficiency design and durability also provide a guarantee for the long-term and stable operation of precision machining equipment.

The motor not starting may be caused by power supply problems, control circuit failures, or faults within the motor itself. If you encounter a situation where the motor fails to start, first check whether the power supply connection is normal and ensure that the voltage meets the requirements of the motor. You can check whether the power switch is properly closed, whether the front-stage fuse is blown, whether the fuses in the motor's main circuit or control circuit are blown, whether power control devices such as contactors are malfunctioning, and whether the wires in the circuit are broken or loose. If the power supply connection is normal, then check the control circuit to ensure that the switches, relays, and controllers are working properly. If all the above checks are correct, it may be necessary to check whether there is a short circuit or open circuit inside the motor. The solution is to repair or replace the damaged components.

The motor overheating is usually caused by an excessive load, a large current, or poor heat dissipation. When you find that the motor is abnormally hot, first check whether the load exceeds the rated range of the motor and make adjustments if necessary. You can use a clamp ammeter to check the current of each phase to ensure it is within the normal range. If the current is normal, then check the motor's heat dissipation system, clean the heat sink, and ensure good air circulation. If the overheating is caused by poor ventilation or high humidity, you can check the motor fan, clean the ventilation duct, increase ventilation, and lower the ambient temperature. If the overheating is caused by frequent starting or excessive forward and reverse rotations, you can reduce the number of forward and reverse rotations of the DC motor, or replace the motor with one that can withstand frequent starting and forward and reverse rotations. For persistent overheating problems, you may need to consider replacing the motor or improving the ventilation conditions.

The unsteady operation of the motor may lead to vibration or noise problems. This situation is usually caused by worn motor bearings, uneven load distribution, or poor contact between the brushes and the commutator. When the motor runs unsteadily, check whether the motor bearings need lubrication or replacement, and ensure that the load is evenly distributed. If the brushes are severely worn, they should be replaced in a timely manner, and check the condition of the commutator to ensure good contact. If the problem is caused by friction between the stator and the rotor, stop the machine immediately for inspection and adjust the air gap.

The decrease in motor efficiency is usually related to internal friction or electrical problems in the motor. First, check the lubrication status of the motor to ensure that there is sufficient lubricating oil and it is not contaminated. If there is a short circuit inside the motor, it will cause the motor to overheat and lead to a decrease in efficiency. When you find that the motor is smoking or you smell a burnt odor, stop the machine immediately for inspection. Sometimes, there are burnt black spots on the commutator segments. In an emergency, you can short-circuit the commutator segments of the coil with insulated wires, and the motor can still continue to run. Secondly, check the electrical system to ensure that there is no short circuit or open circuit in the motor windings. If the above checks are normal, it may be necessary to thoroughly clean and repair the motor, or consider replacing the motor components.

DC motors are mainly composed of components such as the stator, rotor, commutator, brush holder, and brushes. The stator provides the magnetic field, and the rotor is connected to the current through the commutator and brushes. During maintenance, it is necessary to focus on checking the surfaces of the stator and rotor to ensure that there is no dirt or damage, so as to maintain the stability of the magnetic field and the flexibility of the mechanical components. As core components, the commutator and brushes are responsible for the commutation of the current. It is necessary to check the flatness of their contact surfaces and the wear condition of the brushes to prevent excessive wear. The bearings provide support for the operation of the motor, and the cooling system helps with heat dissipation. Attention should be paid to the lubrication of the bearings and the heat dissipation effect of the cooling system.

During the daily routine inspection, pay attention to whether the running sound of the motor is normal and whether there is any abnormal vibration; observe whether the commutator and brushes are overheated; confirm whether the cooling fan is running normally. Regularly clean the motor to prevent the accumulation of dust and oil stains from affecting its performance. According to the frequency of use, replace the bearing lubricating grease every 3 to 6 months, and be careful not to use an excessive amount. At the same time, regularly check whether the fixing bolts of the motor installation are loose to ensure that the motor is firmly installed.

- Motor Overheating: It may be caused by overload operation, cooling system failure, or bearing wear. You can reduce the load, clean the cooling fan, and replace the bearings in a timely manner if they are worn.

- Excessive Brush Sparking: It is usually caused by an uneven surface of the commutator, brush wear, or insufficient spring pressure. You can grind the commutator, replace the brushes, or adjust the spring pressure.

- Abnormal Rotation Speed or Unstable Operation: The possible causes are power supply voltage fluctuations, control system failures, or poor contact of the commutator. It is necessary to check the power supply and controller, and at the same time, clean and adjust the commutator.

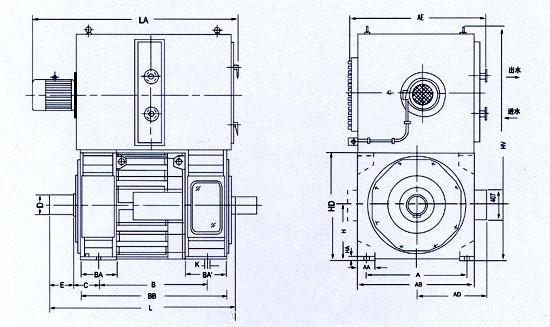

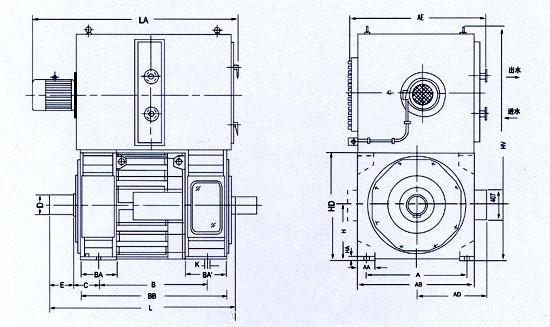

When selecting a Simo DC motor, it is necessary to carefully determine various parameters according to the actual needs. Firstly, regarding the motor type, it is essential to choose an appropriate DC motor by combining the specific application scenario and working requirements. For determining the rated pressure, the load situation should be taken into account to ensure that the motor can withstand the required working pressure. The selection of power should be based on the actual load demand, which not only needs to meet the power requirements of the equipment but also avoid energy waste caused by excessive power. The determination of the rotational speed should be based on the operating speed requirements of the equipment to ensure that the motor can provide an appropriate rotational speed output. In addition, the mechanical structure is also crucial. For example, whether a speed reducer, encoder, etc. are needed should be selected according to the requirements of the actual control system.

Simo DC motors have many excellent performance characteristics. Firstly, they have high precision and a fast response speed, which can accurately control the movement of the machine. They are very suitable for occasions with high-precision motion control requirements, such as in the field of precision instrument processing. Secondly, they have high efficiency and can complete the corresponding work in a relatively short time, greatly improving production efficiency and bringing higher economic benefits to enterprises. Thirdly, they produce less noise, which can reduce environmental noise pollution during operation and improve the comfort of the workplace. They are especially suitable for occasions with strict requirements for noise pollution, such as automated equipment near office spaces.

Simo DC motors are widely used in multiple fields. In the field of robotics, they provide stable power for the precise movement of robots, ensuring that robots can efficiently complete various complex tasks. In the field of automated equipment, their high efficiency and precise control performance make the automated production line more stable and reliable, improving production efficiency and product quality. In the field of textile and printing machinery, Simo DC motors can adapt to complex working environments and provide strong power support for printing and dyeing equipment. In the field of packaging machinery, their characteristics of high precision and high efficiency help to improve the packaging speed and quality.